Computation and Construction in Architecture (CoCoA) Lab

School of Architecture, Design and Planning

School of Architecture, Design and Planning

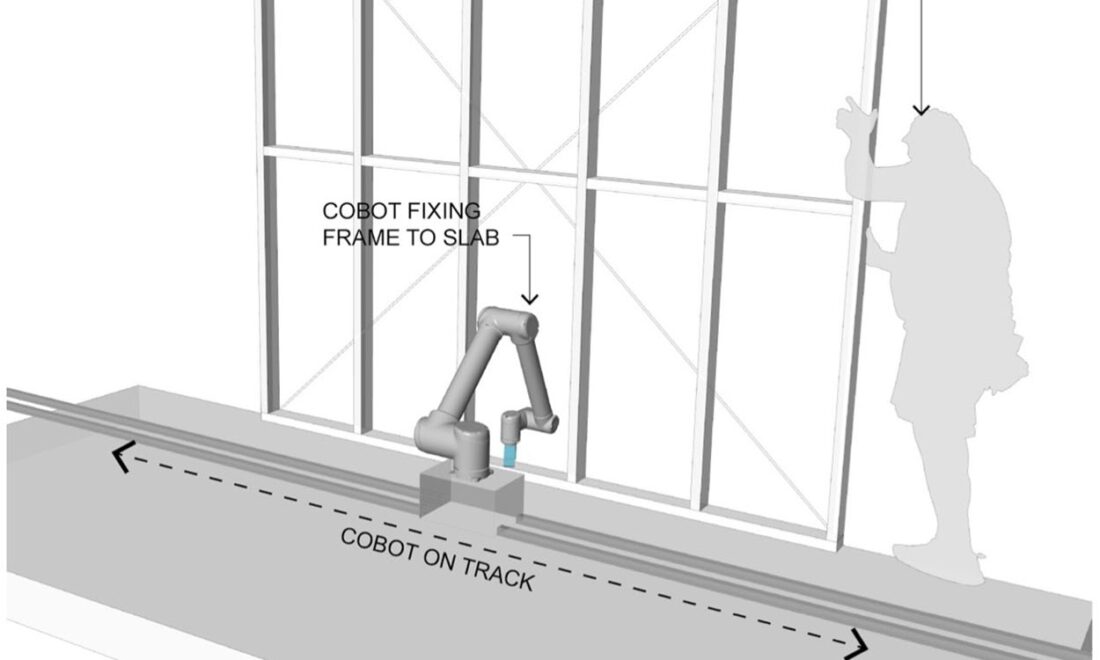

CoBot nailing frame to slab with custom end effector whilst carpenter supports frame

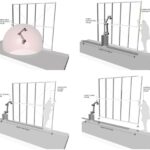

CoBot- Carpenter Collaborative workspace: CoBot reach in static position (top left), CoBot supporting frame whilst carpenter levels (top right), CoBot assisting carpenter sliding frame (bottom left), CoBot assisting carpenter lift frame (bottom right)

Detailed framing actions highlighting how the carpenters use their hands and feet to help prop and stabilize the frames

Human-robot interactions can offer alternatives and new pathways for construction industries, industrial growth and skilled labour, particularly in a context of industry 4.0. This research investigates the potential of collaborative robots (CoBots) for the construction industry and subject matter experts; by surveying industry requirements and assessments of CoBot acceptance; by investing processes and sequences of work protocols for standard architecture robots; and by exploring motion capture and tracking systems for a collaborative framework between human and robot co-workers.

The physical adaptability and versatility of industrial six-axis robots towards construction and manufacturing processes in design, architecture and the built environment have progressed successfully through academic and industry research in recent years. However, applications in architecture remain limited due to lacking computational, sensory and interface capabilities, which is of significance for work processes that require multiple steps, variable toolsets, or sequenced work protocols. A robot’s six degrees of freedom affords extensive movement and thus unprecedented spatial reachability in comparison to other mechanical tools introduced on the market.

With ongoing industrial growth and shortage of skilled labour in the construction industries, the increased demands for production can be answered by a focus on human-robot collaborations, specifically investing in processes and sequences of work protocols instead of product and outcomes of such processes.

Lowered investment costs and multifunctional applications provide advantages for manufacturing, fabrication and construction industries. Instead of developing highly specialized, single-use machines, a standard industrial robot arm can be equipped with a broad spectrum of end effectors (similar to a human hand using different tools) and thus becomes a certified, reliable and increasingly affordable machine – an agent for Industry 4.0.

With ongoing industrial growth and shortage of skilled labour in the construction industries, the increased demands for production can be answered by a focus on human-robot collaborations, specifically investing in processes and sequences of work protocols instead of product and outcomes of such processes. This requires investigation into the potential for close interactions between co-workers with different ‘skillsets’, whereby a human provides extended movement range, fine-motor skills, variable ‘gripper system’ for toolsets through hands, and a robot provides precision, non-fatigue, or repetitive skills.

To this extent, developments in the fast-advancing fields of Collaborative Robots (CoBots) and Human Robot Interactions (HRI), Social Robotics, Human-Computer Interaction (HCI) and Cyber-Physical System (CPS) can also support architecture robotics for development of frameworks, and modes of production and fabrication. Working closely with humans in shared work environments, CoBots could be adopted to perform repetitive, dangerous or specified task sequences with optimized precision. Moreover, the movement, task sequences, construction techniques and tooling processes that evolved through centuries of craftsmanship and trade practices represent a vast potential for joint human-robot collaborations and work interactions if reconsidered as a ‘learning’ framework for material and technique focused demonstrations for construction purposes.